- 中文

Serial No. : AC-E-003

Size(mm):from 1.5mm to 6mm

Material:Polycarbonate

Place of origin:China

Color:Clear, green, blue, bronze, yellow

Support level: A

Registered capital:820

Founded:2005

Number of companies:50-200人

Export scale:

Contact: 何**

E-Mail:Sign In

Tel:Sign In

About US:

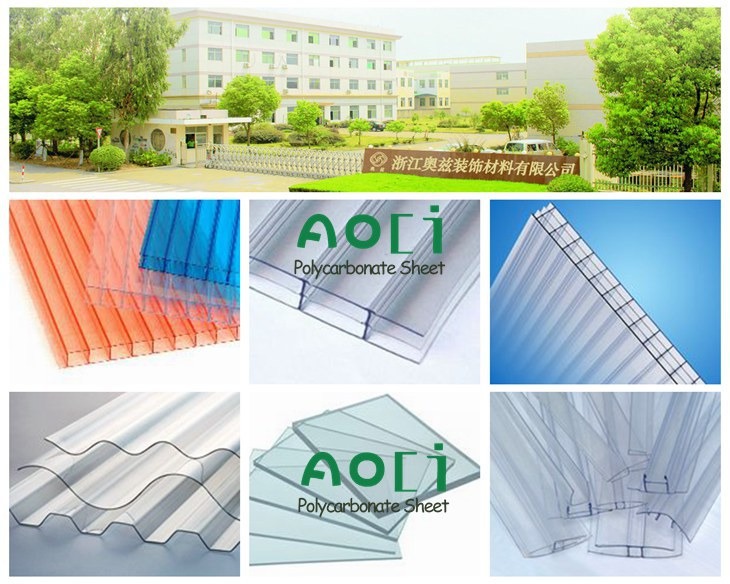

1.Zhejiang Aoci Decoration Materials Co., Ltd locate in Binhai Industrial Zone, Jiaojiang, Taizhou, Zhejiang, China,

specializes in manufacturing Multiwall Polycarbonate Sheet for over 13 years, we are exporter in this field for many years.

2.Using safe, environmentally friendly polycarbonate virgin material and advanced technology to produce various types of PC sheet.

Producing Process of Solid Polycarbonate Sheet

Advantages:

1. Specialize in manufacturing PC sheets for over 13 years

2. 6 Imported Advanced Production Lines

3. Bayer/SABIC 103R virgin material

4. 14,000 tons annual output

5. Verified by ISO9001:2008 & CE

6. Competitive price and good quality

7. UV Protection(Anti-fog is available)

8. OEM acceptable

Trade Terms:

1.Price term: EXW/FOB/C&F/CIF

2.Port: Ningbo or (Shanghai)

3.Payment: by T/T

1)100% payment if the total amount is less than USD10,000;

2)30% deposit and 70% before shipment or balance 70% against the copy of B/L, if the total

amount is more than USD10,000.

4.Delivery time:7-10 working days, subject to the order quantity.

5.MOQ:500 square meters or 1*20GP.

Brief Introduction:

A. Product Range

1). Twin-walls polycarbonate sheet thickness: 4, 5, 6, 8, 10mm. Width: 2100mm.

2). Triple-walls polycarbonate sheet thickness: 8, 10, 12, 16mm. Width: 2100mm.

3). Four-walls polycarbonate sheet thickness: 6, 8, 10, 12, 16mm. Width: 2100mm.

4). Honeycomb polycarbonate sheet thickness: 8, 10, 12mm. Width: 2100mm.

5). Polycarbonate roofing system[Four Layer Rectangule & Honeycomb Structure] thickness: 8, 10, 12mm. Width: 600mm.

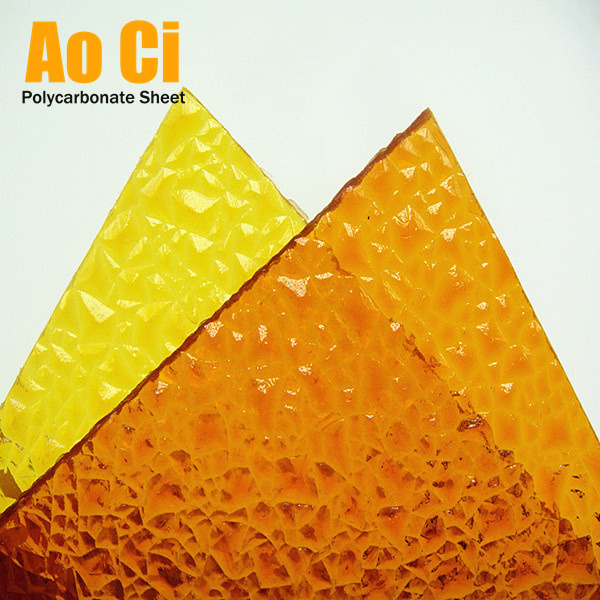

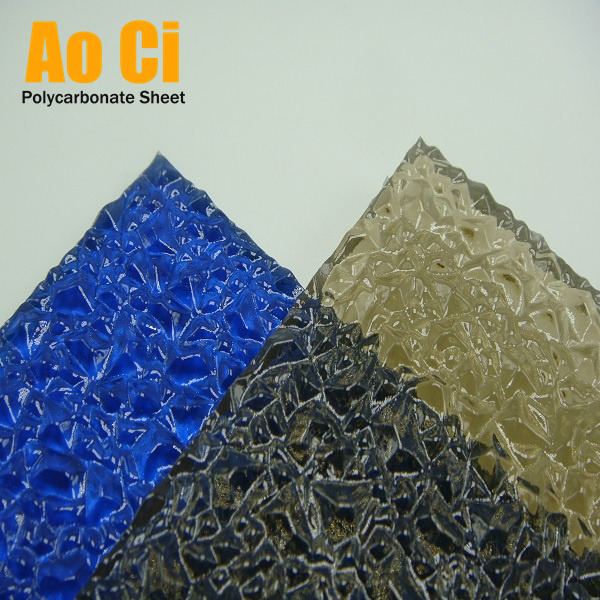

6). Solid polycarbonate sheet [Compact] thickness: 0.9-8.0mm.

Width: 1220, 1560, 1820, 2100mm, Usually 1220x2440mm, 2050mmx3000mm

7). Corrugated polycarbonate sheet [Roma & Greca & Trimdek & Minwave] thickness: 0.8-2.5mm. Width is different.

B. Length: No limit(Recommend 5800, 6000, 11800, 12000mm to suit 20' container & 40' container)

C. Color: clear/transparent, lake blue, green, blue, opal, white, brown/bronze, silvery gray, red, yellow, etc.

Standard Products and Dimensions

| Product | Structure | Thickness(mm) | Weight(Kg/m2) | Width(mm) | Length(mm) | Color |

| PC SOLID SHEETS | SOLID | 1 | 1.2 | 1220 | 2440 | Clear |

| 1.5 | 1.8 | 1560 | 3000 | Bronze | ||

| 2 | 2.4 | 1820 | 5800 | Opal | ||

| 3 | 3.6 | 2100 | Blue | |||

| 4 | 4.8 | Green | ||||

| 5 | 6 | |||||

| 6 | 7.2 | |||||

| 8 | 9.6 |

Tolerances: Thickness±5%, Length±3mm, Width±3mm

Technical Features

U.V.rays protection | 50 micron | Test Method |

Temperature range | -40℃~120℃ |

|

Insulating values | 3.1~3.8W/m² K | GB/T 8484-1987 |

Sound insulation | 14~19dB | GB/T 8485-1987 |

Linear thermal expansion | 0.067mm/m℃ | GBT8484-2002 |

Flame retardant | Bs1¸d0¸t0 | GBT8624-2006 |

ENERGY SAVING

Standardized procedures are used in the building and construction industry to determine the relative energy efficiency of most building products. Insulating values are typically stated in terms of U-value or R-value in the U.S.A., and K-value (the metric equivalent) everywhere else in the world. Where U-factor is concerned, a lower number indicates better energy efficiency.

LIGHTWEIGHT

1/6 the weight of glass and 1/3 the weight of acrylic.As the sheet weight is very low, support structures need not be as

heavy as in the case of traditional materials.This in turn offers savings in structure and installation costs.

LIGHT TRANSMISSION

Light transmission levels in excess of 80% can be achieved with clear and will be maintained throughout the life of the sheet.

Flexible and easy to install

Bends easily into arches. POLIBAY sheets may be cold bent or curved up to their minimum permitted radius, using

polycarbonate’s natural tolerance for cold forming with no need for thermal processing. Curving POLIBAY sheet

beyond this minimum permitted radius induces undue stresses and strains in the glazing sheet, causing premature failure and will void the warranty.

FIRE RESISTANCE

The fire performance of POLIBAY has been independently tested and certified up to Class B1 surface spread of flame when tested to GBT8624-2006, That is, at very high temperatures, the material would melt but flames would not spread.

10 YEAR WARRANTY

Refer to the POLIBAY warranty document for full details of the 10 year warranty.

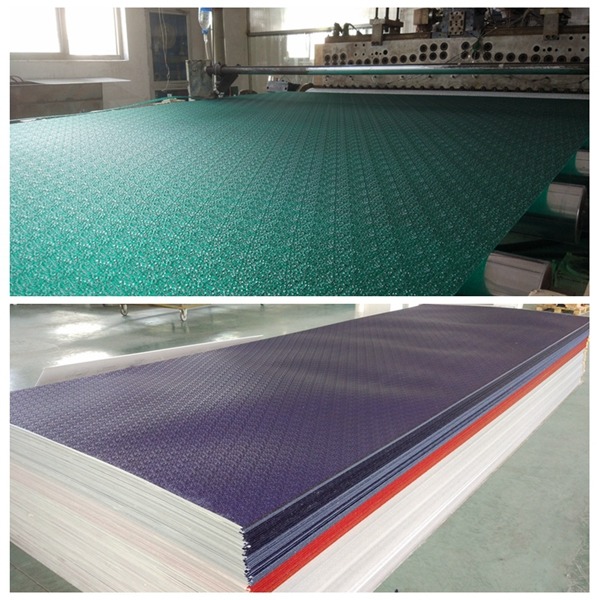

Loading Polycarbonate Sheet Photo

Q: What is Polycarbonate material?

A: Polycarbonate is a very special and unique polymer. The properties that differentiate this polymer from other thermoplastic resins are inherent toughness, transparency, clarity, broad temperature resistance, good electrical properties, and high index of refraction.

Q: What is the impact strength of polycarbonate?

A: Polycarbonate is almost unbreakable. For instance 3 mm solid polycarbonate sheet withstands 4 kg ball dropped from a height of 9.5 m, 3 times in a row, and it does not break or shatter. So, for this reason, polycarbonate is used for police riot shields, ice-hockey rinks, airplane windows, and all applications that require extreme impact resistance.

For more information, Please click here, FAQ

If you want to know more about polycarbonate sheet, pls contact me, we will reply your inquiry timely.

Special discount and protection of sales area provided to our distributors.

Customized desigh is available, OEM is welcomed. Free samples are available. Click “Send ” Now !