- 中文

Serial No. : XLCB150

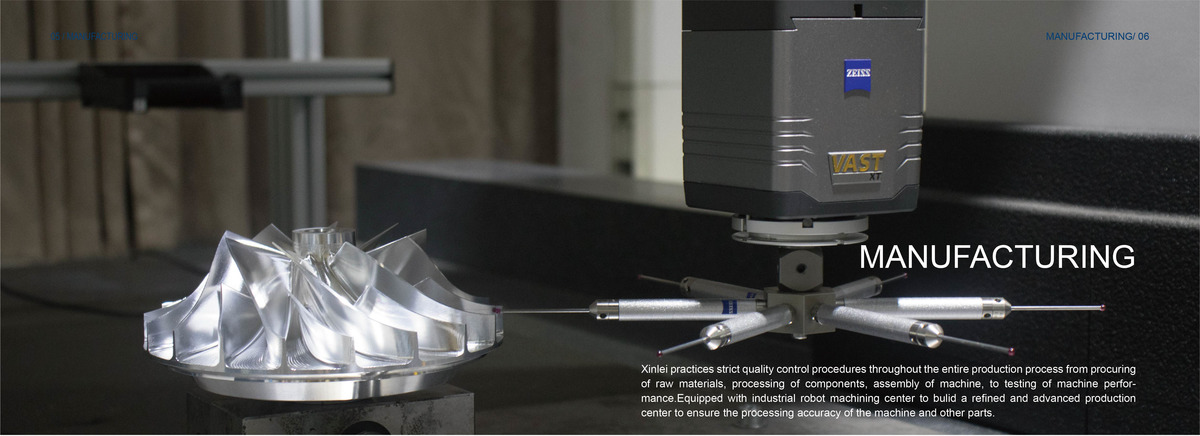

Size(mm):1000*1975*1877

Material:Box body:Carbon steel + ceramic paint anti-corrosion + interior acoustic cotton;Volute:A4C4Volute;Impeller:Advanced aluminum alloy AL7075;principal axis:TI Alloy + rare earth permanent magnet;Intake d

Place of origin:Zhejiang China

Color:Blue or Customize

Support level: A

Registered capital:11789

Founded:2006

Number of companies:500人以上

Export scale:

Contact: 张**

E-Mail:Sign In

Tel:Sign In

The air suspension centrifugal blower is a new concept of single-stage high-speed centrifugal blower phase, which draws lessons from the aircraft turbine engine technology. It adopts three core technologies such as "high-speed direct coupled motor", "air suspension bearing" and "high-precision three-way flow impeller", opening a new era of high efficiency, high performance, low noise and low energy consumption fans. It is a long-life, maintenance free green environmental protection product of oil-free lubrication system.Compared with the traditional roots blower, it can save 30% energy, make noise less than 80 DBA, operate quietly, have long service life, and have no degradation of efficiency in the life cycle.

| Technical Parameter | |||||||

|---|---|---|---|---|---|---|---|

| model | type | power (kW) | displacement (m³/min) | working pressure (mm water column) | machine size (mm) | weight (kg) | outlet pipe diameter |

| XLCB30 | single impeller | 22 | 24 | 4,000 | 700*1600*1380 | 470 | DN150 |

| 21 | 6,000 | 430 | |||||

| 17 | 8,000 | ||||||

| 13 | 10,000 | ||||||

| XLCB50 | single impeller | 37 | 47 | 4,000 | 850*1775*1670 | 560 | DN200 |

| 34 | 6,000 | 700*1600*1380 | 470 | DN150 | |||

| 28 | 8,000 | ||||||

| 22 | 10,000 | ||||||

| XLCB75 | single impeller | 55 | 61 | 4,000 | 850*1775*1670 | 560 | DN200 |

| 51 | 6,000 | ||||||

| 42 | 8,000 | ||||||

| 34 | 10,000 | ||||||

| XLCB100 | single impeller | 75 | 82 | 4,000 | 850*1775*1670 | 560 | DN200 |

| 69 | 6,000 | 610 | |||||

| 55 | 8,000 | ||||||

| 45 | 10,000 | ||||||

| XLCB125 | single impeller | 90 | 101 | 4,000 | 1000*1975*1877 | 820 | DN300 |

| 86 | 6,000 | 850*1775*1670 | 700 | DN200 | |||

| 71 | 8,000 | ||||||

| 53 | 10,000 | ||||||

| XLCB150 | single impeller | 110 | 125 | 4,000 | 1000*1975*1877 | 870 | DN300 |

| 105 | 6,000 | 820 | |||||

| 84 | 8,000 | ||||||

| 65 | 10,000 | ||||||

| XLCB200 | single impeller | 150 | 165 | 4,000 | 1150*1975*1877 | 910 | DN300 |

| 140 | 6,000 | 1000*1975*1877 | 870 | ||||

| 109 | 8,000 | ||||||

| 87 | 10,000 | ||||||

| XLCB250 | single impeller | 185 | 193 | 4,000 | 1300*2350*2100 | 1600 | DN400 |

| 165 | 6,000 | 1150*1975*1877 | 910 | DN300 | |||

| 135 | 8,000 | ||||||

| 105 | 10,000 | ||||||

| XLCB300 | dual impeller | 220 | 266 | 4,000 | 1750*2350*2100 | 2150 | DN500 |

| 210 | 6,000 | 1300*2350*2100 | 1600 | DN400 | |||

| 164 | 8,000 | ||||||

| 133 | 10,000 | DN300 | |||||

| XLCB400 | dual impeller | 300 | 331 | 4,000 | 1750*2350*2100 | 2150 | DN500 |

| 272 | 6,000 | DN400 | |||||

| 216 | 8,000 | ||||||

| 172 | 10,000 | ||||||

Core Technology | |

|---|---|

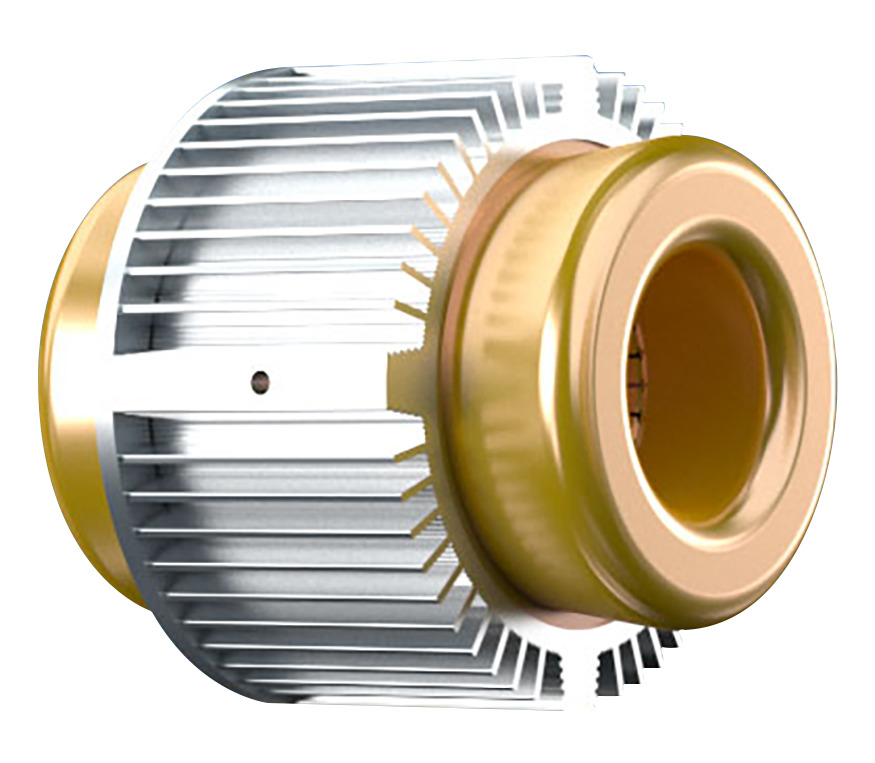

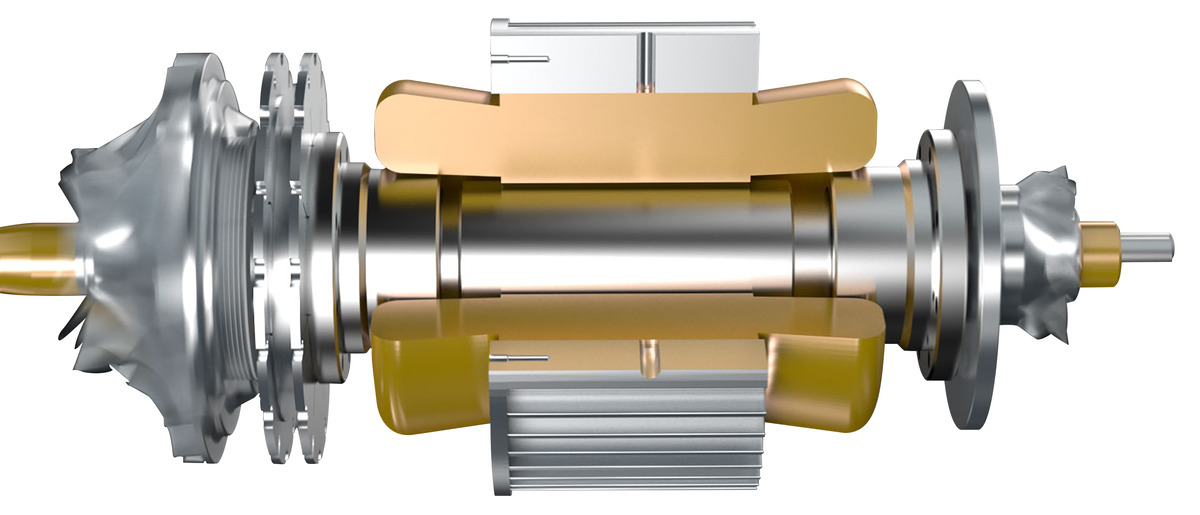

| High speed permanent magnet synchronous motor PMSM(permanent magnet synchronous) motor is optimized for high-speed rotation to minimize the loss of high frequency and achieve the efficiency of 95%. ▶The engine is directly connected with the impeller, and the power transmission efficiency is almost no loss; ▶Permanent magnet is used to maintain high efficiency in long time use; ▶By changing the frequency, the rotation speed can reach 60,000RPM; ▶Accurate speed control; ▶Start-up times over 40,000 Start-Stop Cycle Test; ▶ no need for magnetizing electricity; ▶ Small temperature rise, low heat loss; ▶ The rotating shaft is small in size and free from mechanical friction; ▶ No induction motor slip, partial load can maintain high efficiency; ▶ Accurate speed control and frequency conversion synchronization, no slip motor; |

| |

| Precision machining impeller (PMSM)The impeller is manufactured with state-of-the-art aerodynamic system technology. With the same technology found in aeronautical engineering, our products are sophisticated by design to deliver a highly-efficient and precise processing. ▶AL7075(aviation aluminum) with high hardness heat treatment; ▶Precision maching hrough 5 axis machining, accuracy and durability are improved, with tolerances maintained below 5/1000 mm; ▶The surface is smooth and clean, which is more efficient than casting impeller; ▶High strength, suitable for high temperature and high pressure working conditions; ▶Light weight, less power consumption; ▶The power transfer efficiency can reach 100% due to the direct connection between impeller and shaft; |

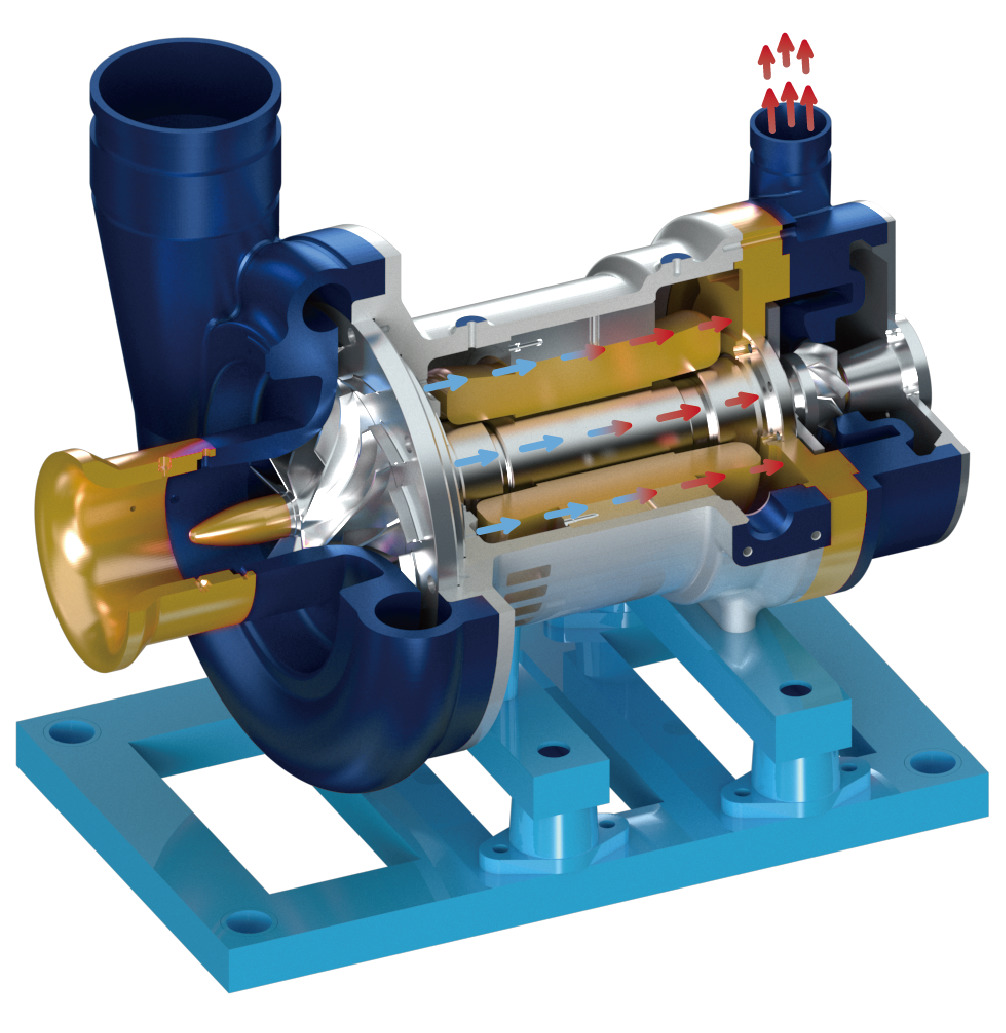

| Air bearing Air bearing includes thrust bearing and radial bearing. Before starting, there is physical contact between the rotating shaft and the bearing. When starting, the rotating shaft and the bearing perform relative movement to form air film so that the rotating shaft is in a suspended state. ▶PMSM(permanent magnet synchronous) motor with 100% oil-free non-contact bearing; ▶Air bearing has simple structure, error-free operation and convenient maintenance; ▶Minimal power loss and high efficiency; ▶After strict testing, the number of start-up of air bearing can reach more than 20,000 times, the service life can reach 20 years (semi-permanent); ▶No vibration, low noise (below 80dB); |

| |

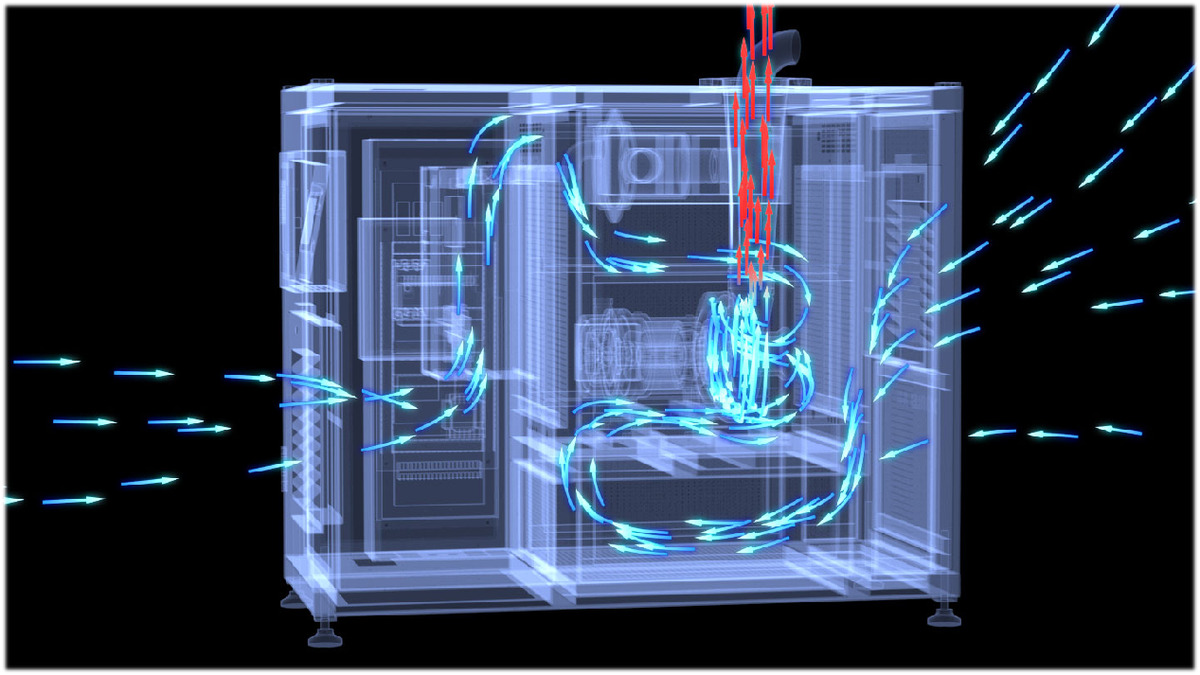

| Efficient cooling system With the latest technology of two-stage air cooling and self cooling mode, separate air flow channels are set inside and outside the main engine reasonably and cleverly to maximize the cooling of the main engine, so as to ensure the stable and reliable operation of the blower system in hot summer. |

| |

| Structure | |

|---|---|

| Intelligent control system -Through the PLC control system to maintain a certain pressure, flow and speed, the control is simple. Chinese display human-computer interface; customers can monitor the operation of the equipment in real time through the touch screen screen; -RS485 port is used to support a variety of communication protocols to realize remote control; -It has surge protection function, maximizes product safety, provides multiple working modes and automatic fault alarm, which is convenient to analyze the cause of fault. |

| High efficiency frequency converter -It adopts well-known brand frequency converter with high stability and reliability; -It provides a minimization algorithm for high-speed rotation; -By adjusting the frequency (Hz), the energy-saving high-speed rotation function is achieved; -Built in DC reactor, can suppress power harmonics, precision operation, soft start; -The air volume of the fan is adjusted by the frequency converter, and the adjustable range is 45% - 100%; -According to the specifications of different fans, the working frequency of frequency converter is generally 400-800hz; -The internal is equipped with a backup capacitor (kinetic energy backup), which can quickly and safely slow down and stop the equipment in case of power failure; |

| Electronic control system |

| Permanent magnet high speed host -PMSM permanent magnet synchronous motor is designed with high-speed rotation optimization, the efficiency can reach over 97%, long-term and high efficiency without attenuation, and precise speed control can be carried out through frequency converter -Precision machining of three-dimensional flow impeller -Non contact air suspension bearing -Two stage air cooling and self cooling mode |

superiority characteristic

Energy-efficient Compared with traditional roots blower, it can reduce power consumption by more than 30%;

Energy-efficient Compared with traditional roots blower, it can reduce power consumption by more than 30%;

Simple operation, intelligent control Intelligent, humanized TOUCH screen, with 5 operating modes and 5 protection functions;

Simple operation, intelligent control Intelligent, humanized TOUCH screen, with 5 operating modes and 5 protection functions;

Low noise, no vibration Noise less than 80 db, no vibration, environmental friendly, no foundation or anchor bolts;

Low noise, no vibration Noise less than 80 db, no vibration, environmental friendly, no foundation or anchor bolts;

No lubrication, no maintenance 100% oil-free floating bearing system, no secondary pollution, no need for regular maintenance or replacement of bearing;

No lubrication, no maintenance 100% oil-free floating bearing system, no secondary pollution, no need for regular maintenance or replacement of bearing;

Highly integrated and easy to install The machine is highly integrated, small in size and light in weight, easy to install;

Highly integrated and easy to install The machine is highly integrated, small in size and light in weight, easy to install;

Long service life, semi-permanent Using air bearing technology, semi-permanent lasts more than 20 years, efficiency does not decline during life cycle;

Long service life, semi-permanent Using air bearing technology, semi-permanent lasts more than 20 years, efficiency does not decline during life cycle;